+86 512 5879 0108

+86 512 5879 0108

Introduction and construction technology of PVC PVC waterproof coil

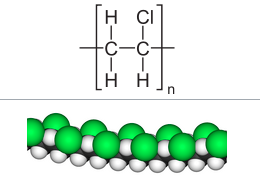

Polyvinyl chloride (PVC) is an important organic polymer compound, and its application covers all areas of life. In daily life, many daily items are made of PVC, such as plastic cups, plastic bags, all kinds of water pipes and wire pipes. In the field of construction, PVC products also occupy an important position and are widely used in the manufacture of many types of pipes, cables and waterproof coils.

Polyvinyl chloride (PVC) waterproof sheet, is a kind of polymer waterproof sheet, the manufacturing of raw materials, mainly includes polyvinyl chloride resin, and supplemented by appropriate modifiers, antioxidants, ultraviolet absorbers, colorants, fillers and plasticizers. After carefully designed kneading, extrusion and calendering process, the sheet waterproof coil is finally formed.

This kind of PVC waterproof coil is widely used in the construction field, mainly for laying waterproof layer, to ensure that the waterproof performance of the building can be improved. Its stable quality, reliable performance, by the industry trust and praise.

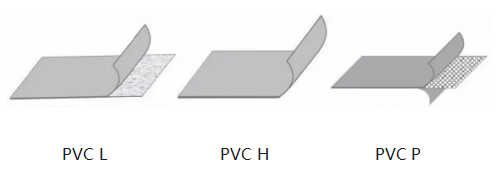

This waterproof coil is subdivided into five categories: the first is homogeneous PVC waterproof coil (Class H), which is a smooth sheet without reinforcing material and no backing material; Secondly, polyvinyl chloride waterproof coil with fiber backing (Class L) is characterized by fiber backing; In addition, the fabric reinforced polyvinyl chloride waterproof coil (Class P), which adds a fabric reinforced layer inside the coil; In addition, glass fiber reinforced polyvinyl chloride waterproof coil (Class G), this kind of coil is characterized by the use of glass fiber for internal reinforcement; Finally, polyvinyl chloride waterproofing coils with fiber backing (Class GL) are reinforced with glass fiber inside, which are not only reinforced with glass fiber inside, but also with fiber backing.

Waterproof coil can be divided into two categories according to its exposed performance: exposed and non-exposed.

PVC waterproof coil, as one of the representatives of polymer waterproof coil, occupies an important position in the current market. At present, the mainstream polymer waterproof coils mainly include: EPDM waterproof coils, polyvinyl chloride (PVC) waterproof coils and thermoplastic polyolefin (TPO) waterproof coils.

EPDM waterproof coil has excellent performance in various application indexes, but its weldability has some shortcomings. Due to its material characteristics, the welding performance is relatively poor. In the actual construction, in order to deal with the lap joint, the adhesive method is used in most cases. However, over time, the adhesive or adhesive tape will age and fail, causing the lap edge to fall off, which may eventually lead to the failure of the overall waterproof layer.

As a new generation of polymer waterproof material, thermoplastic polyolefin (TPO) waterproof coil has excellent performance in application performance, which is comparable to EPDM material, fully demonstrating its excellent waterproof performance.

Polyvinyl chloride (PVC) waterproof coil in the field of polymer coil excellent performance, thanks to its good weldability, mature research and development and production process and perfect supporting construction method. Among the three optional polymer waterproof materials for single-layer roofing system, the application advantage of polyvinyl chloride (PVC) waterproof coil is particularly outstanding, which can be used for external exposure, energy saving, reducing comprehensive cost and ensuring long-term waterproof project quality, etc., making it an ideal waterproof material for large-span metal or concrete structure roofing of major factories and warehouses. In these construction parts with strict requirements for material properties, PVC waterproof coil can give full play to its waterproof effect to ensure the stability and reliability of project quality.

Overview of large area coil construction methods

For the large surface construction of PVC waterproof coil, there are the following main methods:

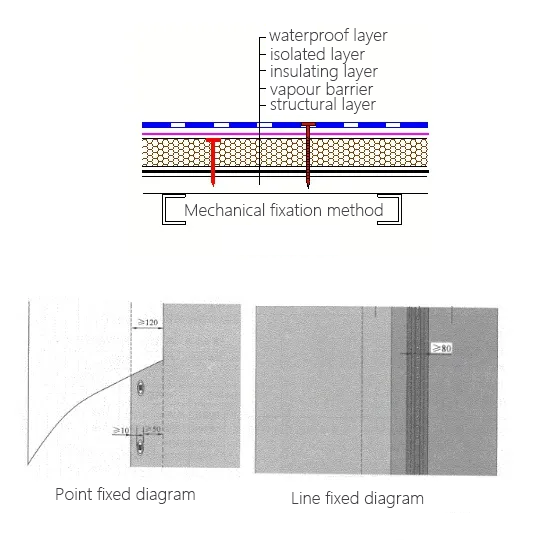

1. Mechanical fixation method

2. Bonding method

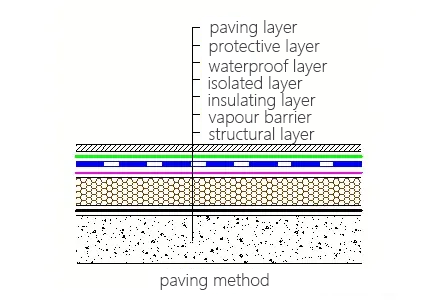

3. Paving method

Among them, the mechanical fixing method is the use of special fixing parts to stabilize the coil on the base construction method, its form can be divided into point fixing and linear fixing. This method is especially suitable for steel structure roofing, light steel roofing and other occasions.

The bonding method is a construction method in which the coil and the base surface are coated with adhesive, and the adhesive adhesive is used to fix the coil on the base surface. This method is widely used in waterproof construction of concrete structure layer. According to the different construction methods, the bonding method can be divided into full bonding method, strip bonding method and point bonding method. Among them, the full adhesion method is to apply the adhesive on the coil and the base surface, the strip adhesion law is to apply the adhesive in the local strip area, and the spot adhesion law is only to apply the adhesive in the spot area for the adhesion construction of the coil.

The paving method is a special construction method, which is characterized in that the whole large surface is not coated with adhesive. Instead, it is glued and fixed within a certain range of the edge of the construction base surface, which is usually 800mm. After that, the upper part is covered with paving material to complete the construction. This method is often used in specific parts such as concrete structure roofing, which can effectively ensure construction quality and efficiency.

Lap joint hot air welding construction method overview:

Although the above three large-area construction methods differ in the specific operation, they all follow a unified standard in the treatment of the lap edge of the coil, that is, the use of hot air welding method. This welding method belongs to the category of non-contact welding, through a special welding machine to generate high heat and have a specific wind pressure strength of hot air, heat the coil under the lap surface until it reaches a molten state. Subsequently, the use of rollers and other tools for compaction fusion, to ensure the solid and complete welding.

Commonly used hot air welding machines include but are not limited to: hot air welding gun, automatic hot air welding machine, etc.

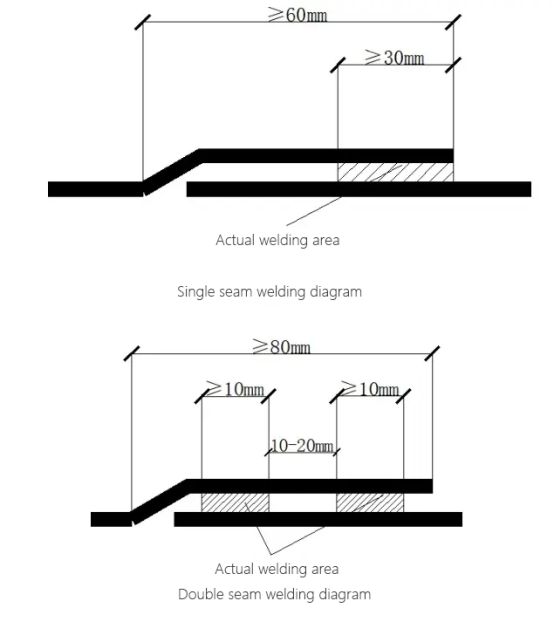

According to the difference in the number of welds, the hot air welding method is subdivided into single seam welding and double seam welding. Specifically, the single seam welding method is mainly applied to the construction practice of industrial and civil construction projects such as single-layer roof and underground building. The double seam welding rule is widely used in the construction of municipal and road bridge projects such as tunnels, artificial lakes and landfill sites.

Tips:

In order to ensure the robustness of the weld, we usually use the method of hooking along the weld one by one for detection. If the crochet needle can Pierce into the inside of the weld somewhere, it indicates that there is a problem such as virtual welding or missing welding, and it needs to be repaired immediately. In addition, in order to check the width of the weld, we use the cutting method, that is, to cut the strip perpendicular to the weld, by observing the actual welding width of the transverse section, you can judge whether it meets the standard requirements.

Common node processing methods:

① T-lap joint is a potential leakage risk point, if there is insufficient heating in the welding process, it may lead to false welding or missing welding problems. To solve this problem, we take measures to first use a scraper to smooth the T-lap edges and corners to ensure that they are smooth, and then carry out real welding operations to ensure the quality of welding.

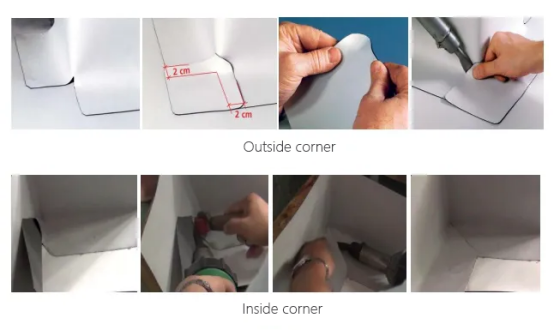

②Outside and inside corner welding: In the actual construction process, Outside and inside corner and other corner parts are very common. When welding in these parts, be sure to ensure the stability of the welding around the bend, bend and cut to prevent leakage caused by poor welding. In order to ensure the construction quality and safety, please strictly abide by the relevant regulations and operation requirements.

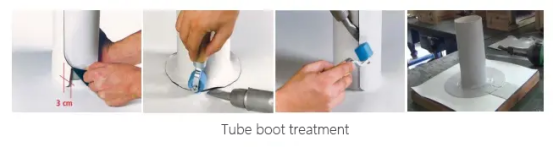

The welding at the root of the pipe is an important construction step, which involves complex processes such as the joint of the horizontal facade and the three-dimensional cutting and encircling of the pipe. In actual construction, these detailed nodes need special attention and treatment to ensure construction quality and safety.

The welding work of the water outlet is very important. This part is affected by water accumulation for a long time, and there is an inevitable gap between the water outlet components and the structure, which makes it a detailed joint part that often leaks in practical construction applications. In order to ensure the quality of the project and the use of safety, must be strictly in accordance with the relevant standards and specifications of the water outlet welding treatment.

ZHANGJIAGANG NEICO TOOLS CO., LTD.

Add.: NO.17-18, Building 6, International Trade City, Tangqiao Town, Zhangjiagang 215600, Jiangsu, China

Mob: +86 139 1570 3340

Tel.: +86 512 5879 0108

Fax: +86 512 5879 0108

Skype: neicotools

E-mail: sales@neicotools.com

Web: www.neicotools.com

Products

Site Map